Product introduction

-

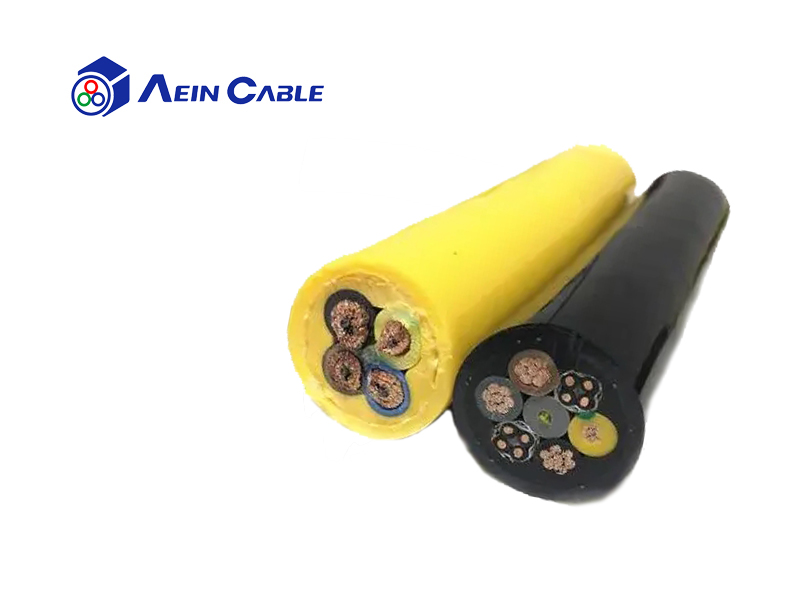

01 Product application Suitable for welding robot applications. For harsh operating conditions (indoors and outdoors) with the highest mechanical stress performance, with both bending and torsional stresses.

-

02 Product characteristics Low adhesion;

Resistant to hydrolysis, micro-organisms, fats, coolants and lubricants; oil resistant according to IEC 60811-2-1;

UV resistant;

Halogen free according to IEC 60754-1.

-

03 Technical certification • Conform to RoHS standard• Conform to 2014/35/EU-Guideline (''Low voltage Directive'') CE

• LABS-/Silicon-free (during production) • We are pleased to produce special versions, other dimensions, core and jacket colours on request.

Structure and specification

Conductor structure: Tinned annealed copper

Conductor class: Superfine stranded, conforming IEC 60228 cl. 6 pt. 4

Core insulation: PUR

Core identification:BK, the number is 1,2 and GNYE

Stranding: Stranded in layers

Outer sheath: PUR

Jacket color: Black (RAL 9005)

Rated voltage:>25:750V(DC);<16:500V(DC)

Test voltage:>25:2000V(AC);<16:1500V(AC)

Bending radius moved: 7,5 x d

Speed self-supporting: .10 m/s, max.

Glide: max. .5 m/sec.

Torque: max. 180°/sec

Conductor length: Maximum. 50 m (VW)

Acceleration: Maximum. 20 m/s² |

Torque: Maximum.60°/s²

Bending cycle:> 500wan |Torque:>300wan-180°/m; > 500wan- 60°/meter

Torsion: +/- 180 °/2m

Temperature

Fixed: -50℃/ +80℃

Move: -30℃ / +80℃

Torsion: -25℃ / +80℃

Burning behavior: Self-extinguishing and flame retardant acc. to IEC60332-1-2,VW-1,FT1

Approvals:CE;UL/CUL If required, UL certification and halogen-free requirements should be specified separately.

Product parameter