Product introduction

-

01 Product application

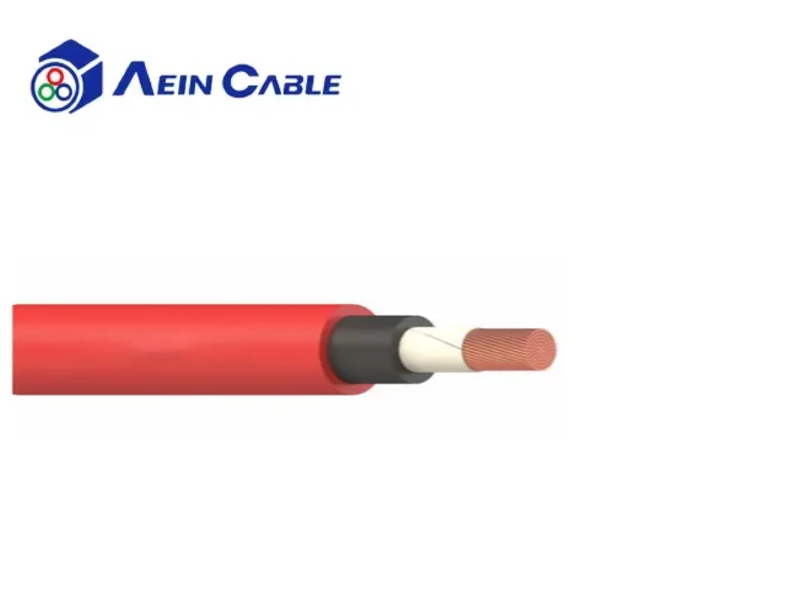

In general single-core cables are used in short lengths e.g. for the connection of switchgear cubicles and for connection of mobile transformer substations to overhead lines. While laying and during operation, care should be taken to protect

the cables against excessive mechanical stresses. Furthermore the general conditions in DIN VDE 0298-3 have to be applied.

-

02 Product characteristics

Reaction to fire EN 60332-1-2, IEC 60332-1-2

Resistance to oil EN 60811-404, IEC 60811-404

Weather resistance Unrestricted use outdoors and indoors, resistant to ozone, UV, and moisture

-

03 Technical certification ·RoHS Compliant

·Complies with 2014/35/EU-Guidelines ("Low Voltage Directive") CE.

• We are pleased to produce special versions, other dimensions, core and jacket colours on request.

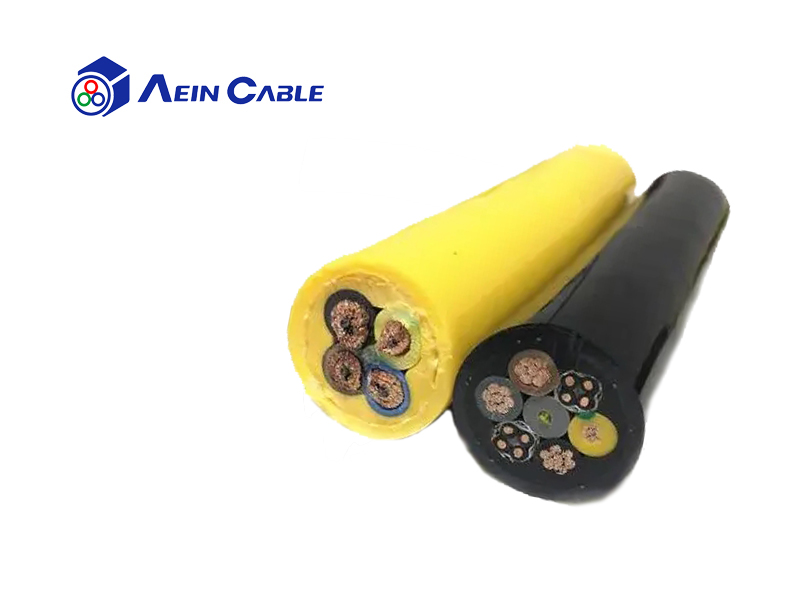

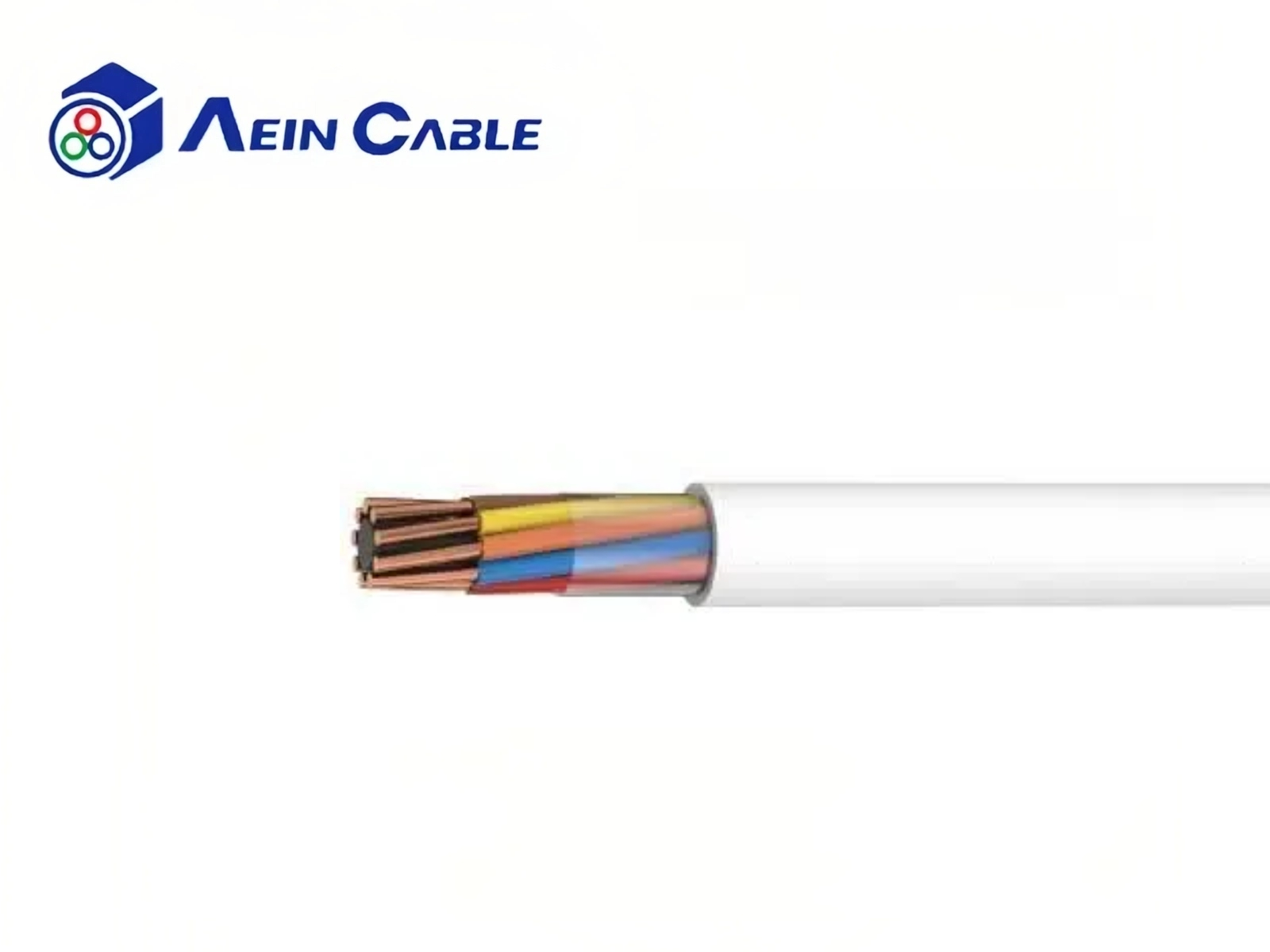

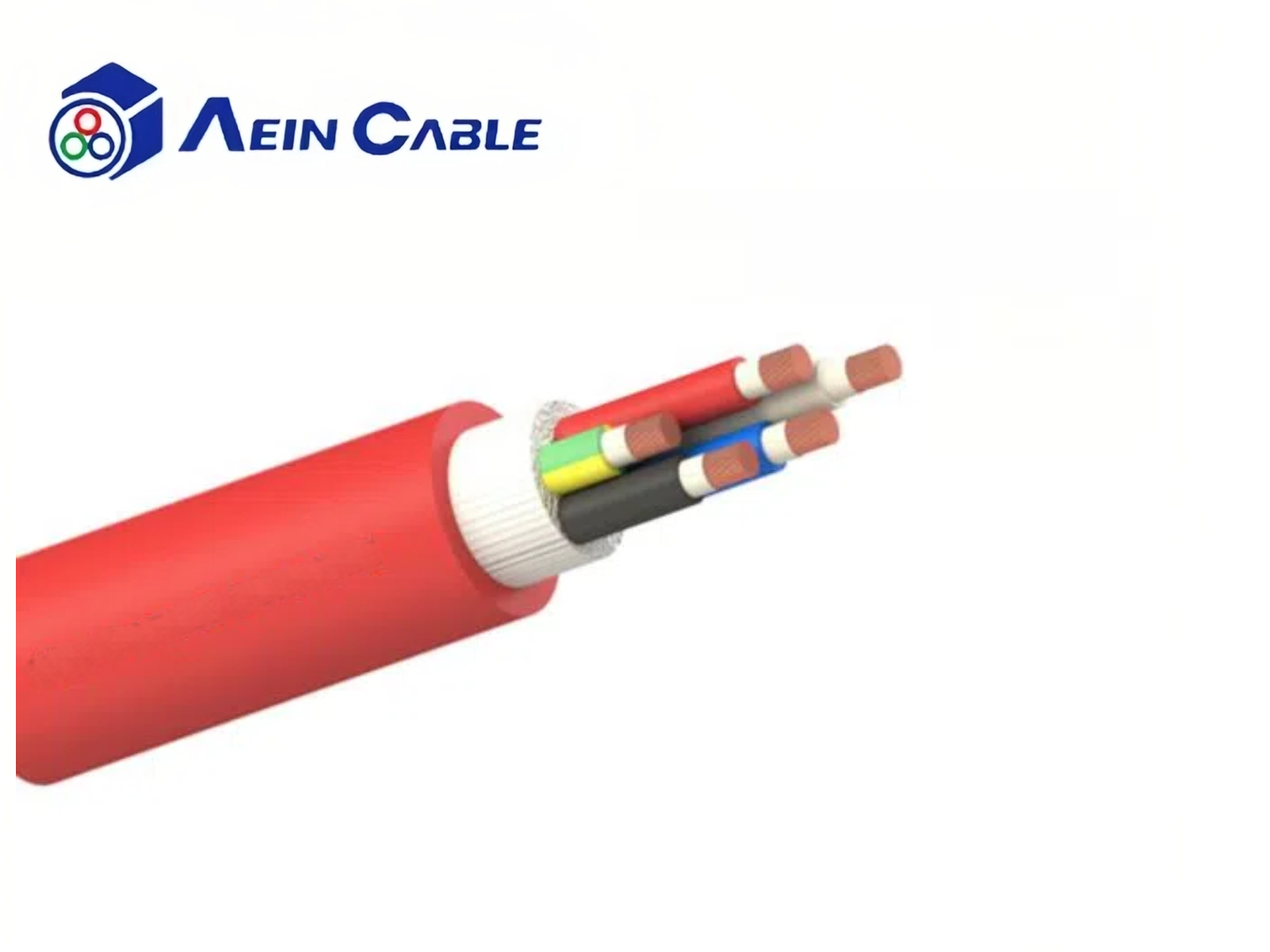

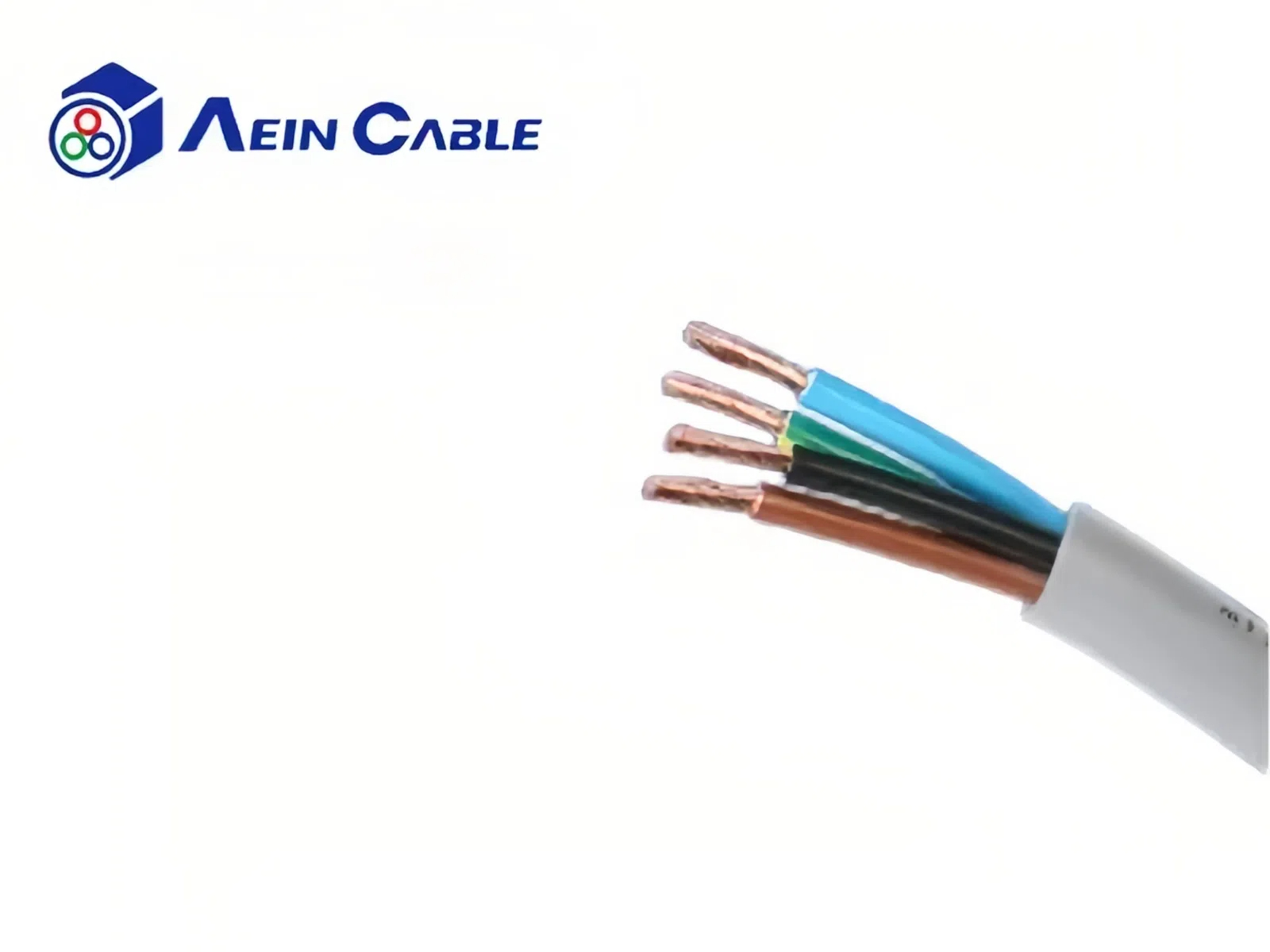

Product structure

Conductor: Finely stranded copper conductor, tinned (class 5), acc. DIN VDE 0295/ IEC 60228

PE-Conductor: Spinning with tinned copper wires 16 mm² or 25 mm²

Insulation: Basic material: EPR, Compound type: 3GI3, acc. DIN VDE 0207 Part 20

Electrical field control: Inner and outer layer of semiconductive rubber compound

Outer sheath: Special compound, Basic material: Chlorinated rubber

Rated voltage 6/10 kV

Max. permissible operating voltage AC 6,9/12 kV

Max. permissible operating voltage DC 9/18 kV

AC test voltage - main cores 17 kV ( Min.)

AC test voltage 17 kV

Max. permissible temperature at conductor 90 °C

Max. short circuit temperature of the conductor 250 °C

Ambient temperature for fix installation min. -40 °C

Ambient temperature for fixed installation min -40 °C ; max +80 °C

Ambient temperature for fix installation max. 80 °C

Ambient temp. in fully flex. operation min. -25 °C

Ambient temperature in fully flexible operation min -25 °C ; max +60 °C

Ambient temp. in fully flex. operation max. 60 °C